The IBC4EU project will develop cost effective and sustainable bifacial interdigitated back contact (IBC) solar cell and module technology on pilot line level.

Based on business cases from the whole value chain – ingot, wafer, cell and module – we will demonstrate that IBC technology is the most promising choice for a fast launch of GW scale PV production in the EU. Cost competitiveness not only against future heterojunction (HJT) and Tunnel oxide passivated contact (TOPCon) technology but also present-day PERC and PERC technology will be demonstrated for the polyZEBRA and POLO IBC cell designs.

To reach this goal, cost-effective production equipment will be developed and eco-design approaches will be employed. This will reduce the use of scarce materials such as silicon metal and silver, while maintaining an indium-free design. Pilot lines, interlinked on all levels of production, wll help to reach GW scale mass production not only on cell but also on ingot, wafer and module level until 2030. The advantage of the chosen IBC technology is that it is based on existing production technology.

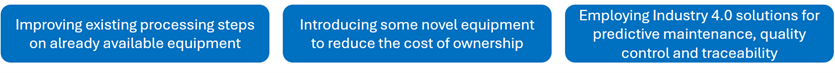

The project will focus on:

The feasibility of the chosen technologies and innovative products will be evaluated by business related parameters as well as performance characteristics. These will be tested in accordance with relevant standards and at demo sites. Furthemore, the environmental impact will be closely monitored and eco-design approaches will be used to reduce the CO2 footprint, increase the resource efficiency and recyclability and improve in terms of circularity potential.

The IBC4EU project is funded by the Horizon Europe Programme for Research and Innovation, and is coordinated by International Solar Energy Research Center Konstanz ISC EV (ISCK).